Avery Dennison North America sites raise over $500k for United Way

By Matthan Evans - Jan 26, 2023

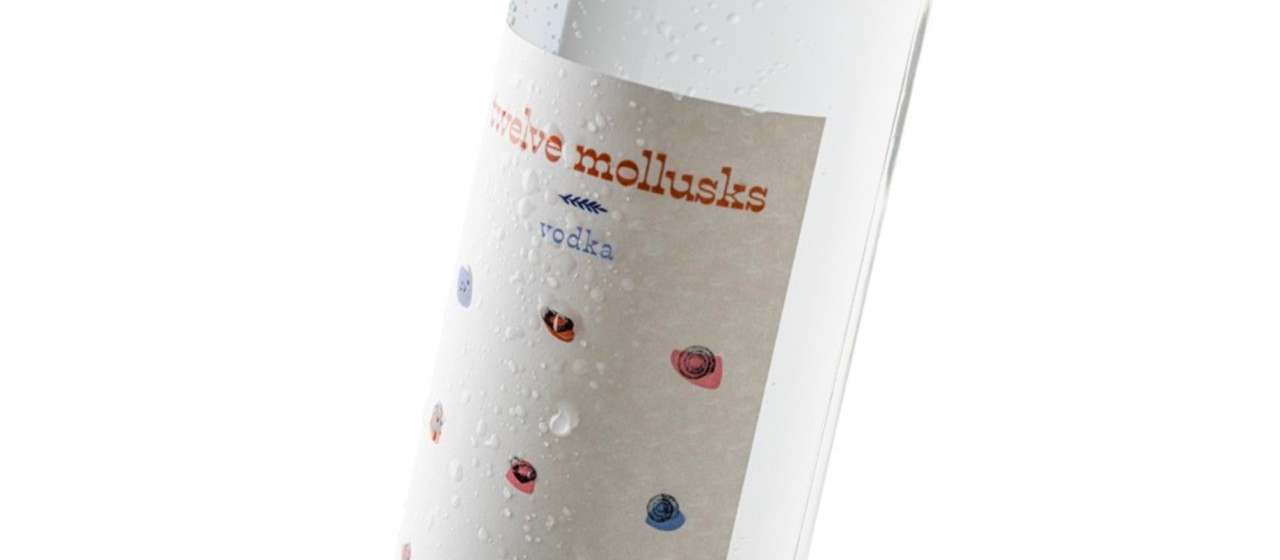

To deliver new levels of performance to the wine and spirits industry, Avery Dennison recently launched its newly developed Z2010 adhesive. What makes Z2010 stand out from other adhesives in our current portfolio? It passes the ice bucket test!

Communications Team

March 2, 2023

Not to be confused with the viral “ice bucket challenge”, our ice bucket test measures how long a bottle of wine with a Z2010 adhesive label can last in a cold bucket of ice without the label peeling or lifting. The result? A Z2010 adhesive label won’t float or show lift for at least eight hours while submerged in a bath of ice water. Very impressive!

Z2010 features an aggressive initial tack, meaning you can't reposition the label once it touches the bottle. This allows for heavier, embellished labels to stay on a bottle even in cold and wet conditions.

Prior to Z2010, converters had to use thicker papers to add texture to labels to make their product stand out on the shelves. Unfortunately, keeping the label on the bottle surface—especially when subject to cold temperatures-was an issue. With Z2010, applying more decorated labels without the risk of lifting is now possible.

Q: What teams worked on the creation and launch of Z2010?

A: Several teams had a hand in making a new product development possible. For Z2010, it started with an adhesive screening by the Mill Hall-based adhesive development team, then transitioned to the Specialty and Durables R&D team for internal testing. From there, the adhesive went to the Cleveland Films Facility (CFF) for the experimental coating run and qualifying. The Pilot Coater supported the converting work and the Central Lab in Building 22 was crucial throughout the project as they completed the standard adhesion and ice bucket test. Once the adhesive was internally tested and qualified, it moved to the customer qualification period, where select customers were able to test the product and provide feedback. The procurement team was instrumental in navigating raw material challenges to support the launch. From a commercial standpoint, the Product Management, MarComm and Sales teams worked in parallel with the other groups to develop the value proposition and marketing materials. It was all hands on deck!

Q: How long was the adhesive in development?

A: The Z2010 adhesive took a few years to develop due to refinements that needed to be made to the material.

Q: Why is the name Z2010? What does it stand for?

A: The name doesn't stand for anything in particular, actually! We already have an existing Z adhesive in the wine and spirits portfolio and we wanted to continue building on the existing portfolio names.

Q: Will all of our labels be made with the Z2010 adhesive in the future?

A: No, Z2010 was created for heavier, more embossed materials, and for customers that want the more aggressive, permanent tack. Other adhesives in our portfolio deliver different results. A customer may choose to use one of the other adhesives depending on their needs.

Q: How is the industry reacting to the launch of Z2010?

A: So far, customer feedback on the performance of Z2010 has been positive.

Q: Is there anything else we should know?

A: The shelf space in a store is limited, especially with so many different competitors in the market. Brands are looking to stand out, which is why the more decorated label is enticing to many brands. Typically, the embossed decoration on a label comes with highs and lows on the material surface, making it penetrable by water. Now, Z2010 makes decorated labels possible since it allows for the label to stay on through the bottle's entire life cycle—from application to the end of use!

By Matthan Evans - Jan 26, 2023